【Applications】

1、oil and gas Anticorrosive factory, pipelining company, construction departments and qualitative inspect branch.

2、also use to gas company and water company pipeline inspecting

3、Shipbuilding, petrochemical plant, factory, machinery plant, enamel factory and bridge engineering anticorrosion-layer inspecting.

4、Pipeline transportation company anticorrosion-layer inspecting

【Characteristic】

1、Microelectronic integrated high voltage generator,to overcome the electrostatic。

2、Full keyboard operation,Improve performance;

3、pinhole automatic counting;

4、High voltage output can Continuous adjustment,auto-save the high voltage value

5、display the The actual test voltage, Ensure the safety of the coating

6、three different the poles to adapt different test

7、when under voltage, automatic shutdown;

8、intelligent charging;

9、Modular structure,Three-proofing design,long service life and reliability。

【Main technical index】

1.Measuring range:A:0.03-3.5mm

B:3.5-10.mm

C:0.03-10.mm

2.Output high voltage:A:0.5-15KV

B:15-35KV

C:0.5-35KV

3. Display: three-digit digital LCD high-definition digital display, display accuracy decimal

4.voltage display accuracy ≤2% , display resolution 100V

5.high-voltage control system: full digital control, performance Stability

6.DC power supply: 12V, 4,000 MA nimh battery lasts more than 12 hours

7.power consumption: < 5w

8. alarm mode: Earphone, buzzer double alarm, sound and Light Alarm

9.shutdown mode: manual shutdown, automatic shutdown, battery under-voltage automatic shutdown

10. high-voltage gun: original import high-voltage generator

11.detection of leaks, automatic memory storage, leak count 1 ~ 999

12.packing: ABS Engineering Plastic Box, three-proof design

13. host size: 165mm × 155mm × 68mm

14.host weight: 1.5 kg with battery, portable

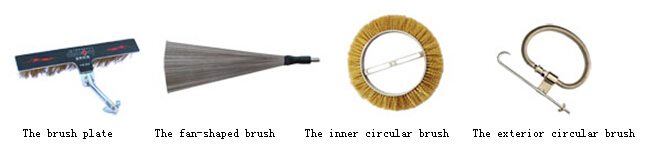

【Accessories】

1、Host x1

2、High voltage probe x1

3、Brush plate x1

4、Fan-shaped brush x1

5、Charge x1

6、Long cable x1

7、Short connecting line x1

8、Connecting magnet x1

9、earth stick x1

10、Rubber gloves x2

11、Manual x1

【Principle】

The detector generates a high DC voltage that is applied to the coating surface through a probe. The detector is connected to the substrate via the high voltage returned. When the probe is passed over a coating flaw, then the electrical circuit is completed and current flows from the probe to the substrate. As a result, audible and visual alarms are activated in the detector and a spark may be produced at the flaw.

【Note】

Standard configuration: The brush plate

Optional configuration: The fan-shaped brush, The inner circular brush,the exterior circular brush