【Characteristic】

1、Low power consumption, small size, light weight;

2、Simple operation;

【Main technical index】

1、Measuring range:A:0.03-3.5mm

B:3.5-10.mm

2、Output high voltage:A:0.5-15KV

B:15-36KV

3、Display:pointer

4、High voltage control system:Ordinary potentiometer adjustment

5、DC supply:12v

6、Consumption:<5w

7、Alarm delay:1-2s

8、High voltage probe:Electronic high voltage generator

9、Packing:metal chest

10、Main dimension: 165mm×155mm×68mm

11、Weight:1.5kg(Including battery)

【Principle】

The detector generates a high DC voltage that is applied to the coating surface through a probe. The detector is connected to the substrate via the high voltage returned. When the probe is passed over a coating flaw, then the electrical circuit is completed and current flows from the probe to the substrate. As a result, audible and visual alarms are activated in the detector and a spark may be produced at the flaw.

【Accessories】

1.Host x1

2.High voltage probe x1

3.Brush plate x1

4.Charge x1

5.Long cable x1

6.Short connecting line x1

7.Connecting magnet x1

8.earth stick x1

9.Rubber gloves x2

10.Manual x1

Note:

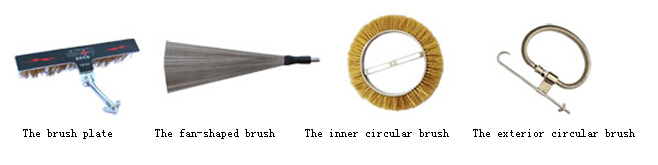

Standard configuration: The brush plate

Optional configuration: The fan-shaped brush, The inner circular brush,the exterior circular brush