【Function】

D1 Porosity Holiday Detector is a special testing equipment used to detect oil and gas pipelines, cables, enamel, metal tank, hull and other protective coatings flaws. It is a simple and practical equipment.s

【Characteristic】

1、Low power consumption, small size, light weight;

2、Simple operation;

【Main technical index】

1、Measuring range:A:0.03-3.5mm

B:3.5-10.mm

C:0.03-10.mm

2、Output high voltage:A:0.5-15KV

B:15-35KV

C:0.5-35KV

3、Display:pointer

4、High voltage control system:Ordinary potentiometer adjustment

5、DC supply:12v

6、Consumption:<5w

7、Alarm delay:1-2s

8、High voltage probe:Electronic high voltage generator

9、Packing:metal chest

10、Main dimension: 165mm×155mm×68mm

11、Weight:1.5kg(Including battery)

【Accessories】

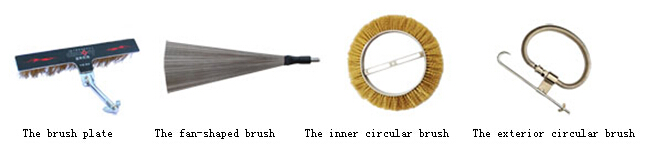

Charger, high pressure gloves, long cable, short connecting line, Connecting magnet, earth rod, The brush plate, Manual

【Principle】

The detector generates a high DC voltage that is applied to the coating surface through a probe. The detector is connected to the substrate via the high voltage returned. When the probe is passed over a coating flaw, then the electrical circuit is completed and current flows from the probe to the substrate. As a result, audible and visual alarms are activated in the detector and a spark may be produced at the flaw.

【Note】

Standard configuration: The brush plate

Optional configuration: The fan-shaped brush, The inner circular brush,the exterior circular brush